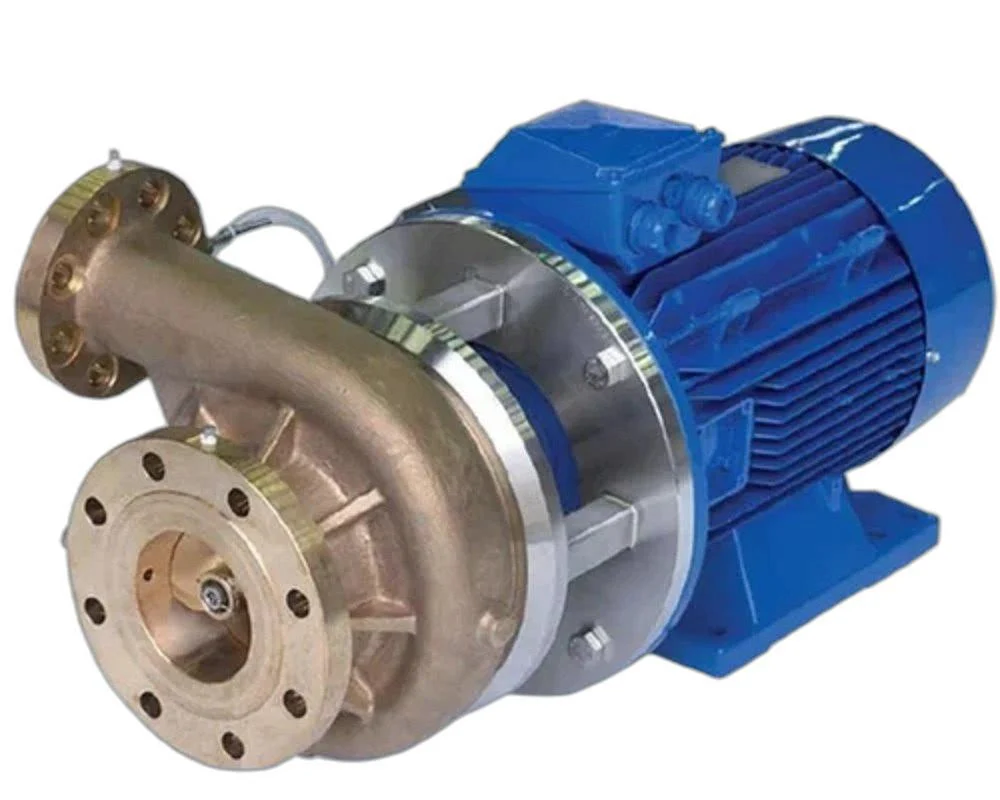

| Max Flow Rate | 300 lit/ min |

|---|---|

| Model | CP |

| Type of end use | Industrial |

| Motor Phase | Three Phase |

| Power Source | Electric |

| Material of Construction | Cast Iron, Bronze |

| Pressure | 4 Kg/Cm2 and above |

| Price | 13 Lakh Per Piece |

Are You Looking for a Cryogenic Centrifugal Transfer Pump Manufacturers in India? Ashoka Compressor will be your one-stop solution. Cryogenic centrifugal transfer pumps use centrifugal force to transfer liquids. They consist of an impeller that rotates inside a housing. The impeller blades draw in the liquid at the pump inlet and accelerate it outward due to centrifugal force. Cryogenic centrifugal transfer pumps are a type of pump specifically designed to transfer cryogenic liquids. Cryogenic liquids are extremely cold liquids, typically at temperatures below -150°C (-238°F). Some common cryogenic liquids include liquefied natural gas (LNG), oxygen (LOX), nitrogen (LIN), and hydrogen (LH2).

This increases the velocity and pressure of the liquid, allowing it to be transferred to its destination. We used advanced and latest technologies to manufacture the various cryogenic pump products which will reduce the manpower and make it easier for industrial purposes. Ashoka Compressor is one of the Leading manufacturers of cryogenic centrifugal transfer pumps in Noida, Delhi NCR, and Faridabad. Find high-quality pumps for your industrial needs.

Durability and Reliability: These pumps are designed to operate in harsh conditions with minimal maintenance.

High Hydraulic Efficiency: They are designed to transfer liquids with minimal energy loss.

Low NPSH Required: Net positive suction head (NPSH) is a critical parameter for centrifugal pumps. Cryogenic centrifugal transfer pumps can operate with a low NPSH, making them suitable for various applications.

Longevity Mechanical Seal: Special seals are used to prevent leaks of the cryogenic liquid at the shaft penetration point.

Material Compatibility: The pump housing and components are typically made from materials compatible with cryogenic liquids, such as stainless steel or special alloys.

Our price of centrifugal pumps is 13 lac Per Piece which is more affordable and reliable than others. We have lots of cryogenic products like cryogenic reciprocating pumps, cryogenic liquid oxygen, and nitrogen pumps. We at Ashoka Compressor are one of the Best Cryogenic pump manufacturers, Suppliers, and exporters in India Deliver products right to your needs and requirements.

Feel Free To Contact Us